Jack's & stands for hire

- Strong but light steel construction.

- Wide base for stability even on uneven ground.

- Can easily be used to level drum.

- Capacity of 3 tonne up to 2.2 metres and 5 tonne up to 3 metres.

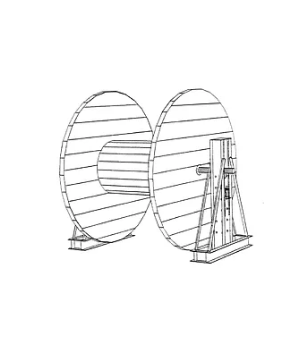

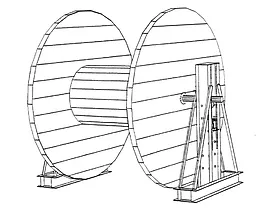

Instructions For 3 Tonne & 5 Tonne Cable Jacks

WARNING pinch points exist between drums, shafts and fittings of these stands. Care should be taken during assembly, and loads should not be applied to shafts unless hands are clear. Gloves should be worn. Never put fingers through holes.

Place one frame either side of cable drum so that the shaft hole lines up with the slot in the middle of the stand. Slide shaft through the drum and stands so that it has an equal amount protruding from either end. In some cases it is beneficial to place a spacer on the shaft between the drum and the stand, to stop the drum travelling along the shaft as it rotates. These can be cut from a scrap of conduit.

Now carry out the following in each stand.

Place two pins in through the stand in the second set of holes from the bottom.

Place the steel channel section on top of the pins flat side up. It can straddle the pins or sit on top of them. But make sure it is supported by both pins at low settings.

Slide the aluminium block up into the stand, curved side up.

Place the bottle jack between the channel and the aluminium block. Locate the top of the jack in the hole in the bottom of the aluminium block.

With one hand under the channel lift the set of fittings up under the shaft, taking the two pins out at the same time.

Place the pins in the highest holes available under the steel channel.

The bottle jack has a screw adjustment in the top of the ram. This can be used to take up the slack between the aluminium block and the shaft.

When all the fittings are set as above in both stands the drum can now be lifted by tightening the pressure release valve on the bottle jack and pumping the jack.

The drum need only be lifted enough to clear the ground as it rotates.

The drum should be lowered by turning the release valve. ONE TURN ONLY.

Five tonne jacks are fitted with outrigger legs. These are for stabilising the stands on rough ground, or if they are used on tall drums. If they are used, they may need to have a pad under their feet to stop them sinking into the ground.

If it is necessary to lubricate the shaft, then grease can be applied between the shaft and the hole in the drum, not between the shaft and the aluminium block.

NEVER USE YOUR FINGER TO APPLY GREASE.

Some drums are too small to allow room for the fittings under the shaft. There is a method of over coming this problem that is best described verbally.

Call us on 02 9772 2309 for this or any other further information.

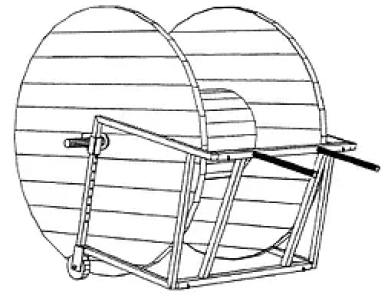

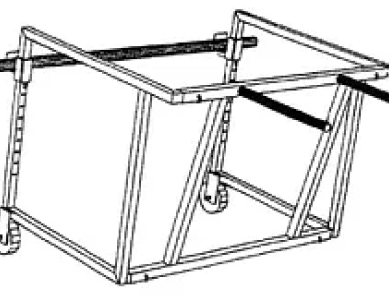

Mobile Cable Stand

Assemble the stand. The drum should be placed so that, when lifted, the cable comes off the top of the drum and over the handles. Put the shaft through the drum to be lifted. Wheel the stand up to the drum.

Adjust the sliding hooks so that they are just above the shaft. Lift the handles so that the hooks drop below the shaft and engage the shaft with the hooks. Put one foot on the bottom bar of the frame and push down on it and the handles at the same time. This should lift the drum.

If the drum still touches the ground as it rotates, carefully lift the handles to lower the drum and move the hooks one hole higher. Repeat the lifting process.

If the stand is to be wheeled any distance, with or without a drum on it, it should be pulled handles first rather than pushed.

- For drums up to 1600mm in diameter.

- 900mm wide and up to 1000kg.

- Allows for easy pick up, relocation and unrolling of cable drums.

- Dismantles for easy transport and storage.

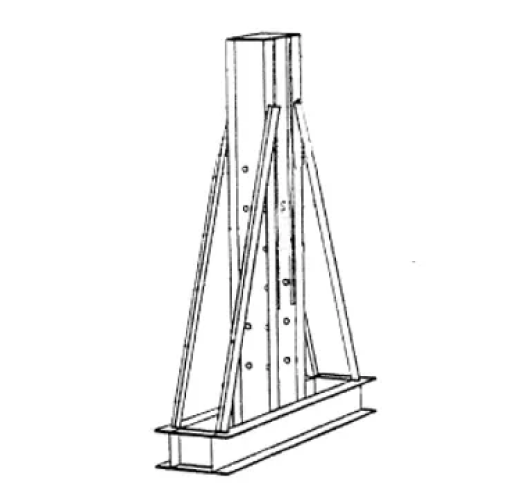

Rope Drum Stand

Place shaft through drum.

Place ‘A’ frames on shaft in a horizontal position, one on either side of drum. Both on the same angle, and with longer end of pipe on drum side.

Raise drum by lifting both handles on top of ‘A frame at the same time.

Get In Touch