The Best Winches in Sydney

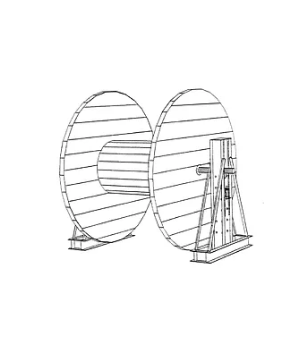

Uni (Concrete) Mount & Towbar Mount

- Designed for both underground and cable tray installations.

- Rated at 1600kg pulling force. (It is not the same as the cable weight.)

- Gauge indicates pulling force exerted on cable.

- Maximum pulling force can be pre-set.

- Compact size. Fits in most confined spaces found in cable installation.

- A 7kva generator or 10amp lead can power it.

- We also have Petrol and battery winch hire available.

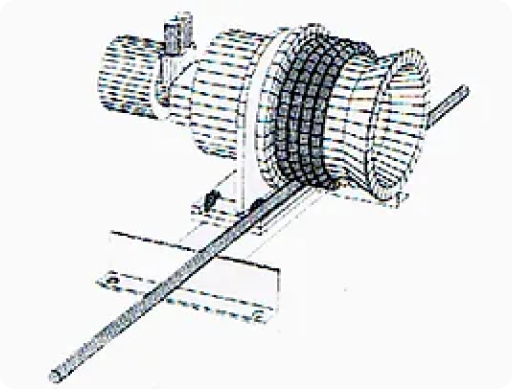

Thank you for hiring the Cabling Equipment Australia Pty Ltd cable hauling winch. This product's design considers the needs of electrical contractors. It was designed to be simple while maintaining safety and versatility. It is a powerful machine that should be used with caution. Only operators who have been instructed to use it should use it. This winch must not be used for vertical pulls. It is for pulling loads that only move when the winch.

Before starting the winch, you should carry out a few basic checks:

- Check the hydraulic oil level in the sight glass on the side of the tank. It is unnecessary to have the tank full, as the winch will operate with only 15cm of oil. The oil level will only vary with leakage. If the oil level is below the sight glass, tilting the tank towards the glass can give a rough estimate of the oil level. We check oil levels regularly, and winches always have enough oil.

- Check the entire machine visually to ensure it is electrically and mechanically sound. Check the hoses and exposed hydraulic components for leaks or damage. Make sure the quick-release couplings are clean. Phone us if the couplings are leaking.

Universal Mount Can be bolted to concrete, wall or ceiling

Towbar Mount - Using vehicle as anchor

Mounting The Winch

- Assemble the mounting system to be used and secure it in position. The universal mount should be secured with a minimum 12mm bolt. Remember: The two hooks on the mounting plate ALWAYS go to the load side.

- If using a towbar mount, the feet of the mount should not be braced against any obstruction on the ground (such as chocks). The mount should be secured to a vehicle, which is the only anchor point. The tow bar on the vehicle must be strong enough to take the forces exerted by the winch. Stand clear of vehicle during winch operation, as vehicle movement is uncommon but possible. Vehicle wheels should be chocked. The safety chain is for additional safety when the mount is coupled to a tow bar. It is not to be used as the only connection point.

- Fit the base plate on the winch head to the mounting plate on the mounting bracket. Secure with pin and clip.

- Connect the pump to the capstan via the quick-release hydraulic couplings. Ensure the winch capstan is clear of obstruction. Wait to fit the rope. Turn on the pump and check again for leaks. The capstan should now be turning anti-clockwise. The load is drawn from below the capstan.

Rope Selection

Only use a rope that is adequate for the load. A safety margin of at least 4:1 should be allowed between the rope's rated breaking strain and the winch's load setting. The winch provides up to 2000 kg of pulling force, and the rope used should be 8000 kg, breaking strain or higher. This margin prevents the rope from being subjected to sharp edges, heat or abrasion. The rope should be checked visually for wear when it is being laid before every pull. Always use a rope with minimal stretch characteristics. Some ropes are very dangerous when used for pulling cable. Never use steel wire rope on th

Fitting Tow Rope Around Capstan

Before tensioning the rope, ensure the area between the capstan and the pit exit is clear. Do not allow anyone to stand between the capstan and the load. No one must be near the pinch point where the rope comes onto the capstan.

Start by wrapping the towrope around the capstan once to get a feel for its movement. To begin pulling, lean back gently with the rope to take up tension and tighten the rope on the capstan. To stop pulling, let the rope slack on the capstan and slip.

The operator should exert at most 20kg by hand. When this is exceeded, slowly release the tension on the rope, wrap another loop around the capstan (keeping hands clear of the capstan), and slowly pull up the tension again. The rope must be allowed to slip a little against the capstan. This allows the rope coming onto the capstan to push the previous laps of rope out along the capstan. If you do not do this, the rope will overlap and lock itself onto the capstan. In this case, stop the pump immediately and carefully free up the rope. Call for advice on this.

- NEVER WRAP ROPE AROUND HAND OR ANY OTHER PART OF YOUR BODY.

- Avoid holding the tensioned rope stationary against the rotating capstan. Friction will burn the rope.

- Never allow the rope to cross over itself on the capstan. You can avoid this by letting the rope slip slightly against the capstan.

- Never stand in line with loaded rope. Stand to the side to avoid being whipped by rope in the event of breakage.

- Ensure the rope does not become entangled with your feet during the pull. It is advisable to keep the rope 2-3 meters from yours as the pull progresses.

Two-Stage Pump

The power pack is fitted with two pumps. Between zero and 1000 PSI, both pumps put their oil through the hydraulic motor. At pressures above 1000 PSI, one of the pumps diverts oil back to the tank to shed some of the load, slowing the winch to half speed.

Powering The Winch From A Generator

A generator of 7 kva or larger capacity is required to run this winch. Operating from a generator may cause starting and running difficulties. In this case, please contact us.

Force Indicating Gauge

The operator can always know the pulling force exerted on the cable by reading the gauge fitted to the pump. This gauge shows both hydraulic pressure in P.S.I. and pulling force in kg force.

Maximum pulling force can be pre-set. Call us for advice—only change settings after first contacting us.

Warning

An operating pressure greater than 2000 P.S.I. will exceed the rated load of the pump motor.

For further clarification of these instructions or any other queries phone

0408 423 188.

Get In Touch